-40%

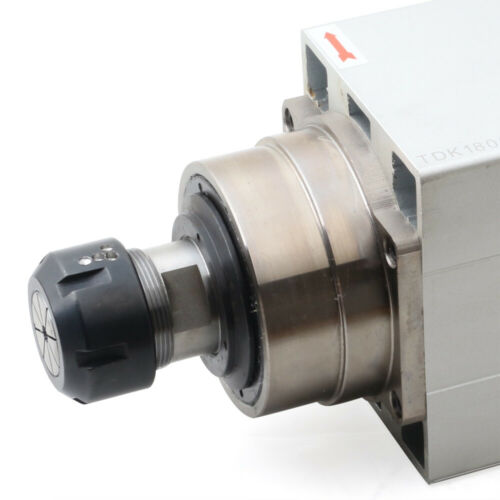

Air-cooled CNC Spindle Motor 4500W 380V 300Hz 18000rpm NC Engraving US SHIP

$ 231.91

- Description

- Size Guide

Description

Store categorySign Up Now !

You may also like

Air-cooled CNC Spindle Motor 4.5KW 380V 300Hz 18000rpm NC Engraving US

Product Description

Note:

This item does Not Contain Frequency Converter, needs to be purchased by yourself.

Specification:

Power: 4.5KW

Voltage: 380V

Current: 9.5A

Diameter: 120mm(4.7 inch)

Intersecting surface: 120*103mm(4.7*4.06 inch)

Shaft connection: ER32

Spindle length: 328mm(12.9 inch)

Speed: 0 ~ 18000rpm

Material: 304 stainless steel

Maximum speed: 18,000 rev / min

Maximum operating frequency: 300Hz

Radial runout: 0.01mm

Coaxial degree: 0.025mm

Dimensions: 120 * 328mm(4.7*12.9 inch)

Clamping diameter: ER32 collet,

Nut model: ER32 type

Speed mode: through the inverter to adjust the output voltage and frequency can be achieved 0-18000 stepless

Cooling: air cooling mode

Lubrication: high temperature grease

Instruction manual

1.

Preparation before installation

1. The working environment temperature of the GDF series air-cooled electric spindle is usually -10 °C ~ 40 °C.

2. Before starting the installation, first turn the shaft of the air-cooled electric spindle by hand. It should be flexible and free from blockage.

3. Check the stator insulation resistance of the stator with a 500V shaker of not less than 50MΩ.

2.

Use correctly

1. Select the inverter to match the voltage, power and frequency of the air-cooled electric spindle. Special Note: When installing the fixing screws on the square air-cooled electric spindle, you must apply thread glue to prevent loosening!

2. Connect the inverter to the three-phase power supply of the air-cooled electric main shaft, and then connect the inverter to the external power supply to observe whether the rotation direction of the air-cooled electric main shaft is consistent with the direction indicated by the air-cooled electric main shaft. If it is inconsistent, it should be shut down immediately and air-cooled. The motor spindle is strictly prohibited from operating in the wrong direction of rotation. The connection between the air-cooled electric spindle and the inverter should not exceed 25m.

3. When installing the tool, the air-cooled electric spindle should remove the dirt on the surface of the shaft head taper and the spring chuck to avoid reducing the precision. Special tools should be used when clamping and removing tools. Be careful not to use excessive force during clamping and disassembly.

4. Due to the limitation of the limit speed of grease lubrication of precision angular contact ball bearings, the air-cooled electric spindle is not allowed to run at over speed. Overspeed operation can cause the precision angular contact ball bearing to burn out.

5. When using the air-cooled electric spindle, the vacuum cleaner should be used in combination to clean the dust generated during the process to avoid the heat generated by the air-cooled electric spindle. In severe cases, the air-cooled electric spindle will burn out.

6. When the air-cooled electric main shaft is working normally, if there is any abnormal sound appearing on the air-cooled electric main shaft, the abnormal sound should be shut down and checked in time. Second, the wind-cooled electric spindle is heated and the vibration is stable. If the heat and vibration are intensified, the shutdown is checked in time. Third, see if the surface quality of the processed surface is stable, such as unstable and timely shutdown inspection.

3.

The problem often occurs in the operation of the electric spindle

The air-cooled electric spindle often encounters heat during normal operation. Always check whether the air-cooled electric spindle's outer casing and air duct are clogged with dust. If the dust is clogged, it should be cleaned up in time. If it is not cleaned up in time, the air-cooled electric spindle will be heated, causing the air-cooled electric spindle to burn out in severe cases.

4.

maintenance and maintenance

1. When the air-cooled electric spindle is running and the sound or vibration is abnormal, stop the bearing immediately and replace the new bearing if necessary. When an abnormal smell or sudden stop occurs during operation, the power should be cut off immediately. The stator-to-ground resistance and three-phase resistance should be measured with a shaker. If the insulation resistance is lost, the stator should be burned out.

2. When the air-cooled electric spindle is out of service for a long time, the shaft head and the taper hole of the air-cooled electric spindle should be rust-proofed. After the air-cooled electric spindle is stored or deactivated for 6 months, it must be replaced with new grease before it can be used, otherwise it will affect the life of the air-cooled electric spindle.

3. In order to extend the service life of the air-cooled electric main shaft, the new air-cooled electric main shaft or the air-cooled electric main shaft with new bearings should be divided into 4 to 8 speeds within the speed range, and each speed should be increased after 30 minutes, avoiding direct High speed operation shortens the service life of bearings. After the holiday, the air-cooled electric spindle is turned on for half an hour after the start-up, and then the work starts.

Payment

Delivery details

Terms of sales

About us

Contact us

Payment

We accept ebay payment 。

Fees such as import duties, taxes are not included in the item price or shipping costs. These charges are the buyer's responsibility.

Delivery details

Shipping:

The item will be shipped from our US warehouse to United States, which is more faster than from aboard.

2-9 working days to: USA

Terms of sales

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

About us

Your satis

faction is our ultimate goal. We work hard to earn your trust and future business. Our certified technicians have tested each item before shipping. The unit comes with 1 year limited warranty on all manufacturing defects.

a) If you receive a defective item, you may return it or ask for a discount. Please contact us within 14 days after you receive the package.

b) What you returned must be intact and in its original packaging as re? u. Customer is responsible for shipping costs of the returned item.

c) We will cover the cost of shipping back t with the shipping rate indicated in the registration page. We will send you a new unit or refund the full payment you paid.

Thank you.

Contact us

Business Hour

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

Feedback

On Jun-25-21 at 00:07:21 PDT, seller added the following information:

On Jul-08-21 at 01:17:20 PDT, seller added the following information: